Innertube valve stem sleeves

Written by Parker Hall

History

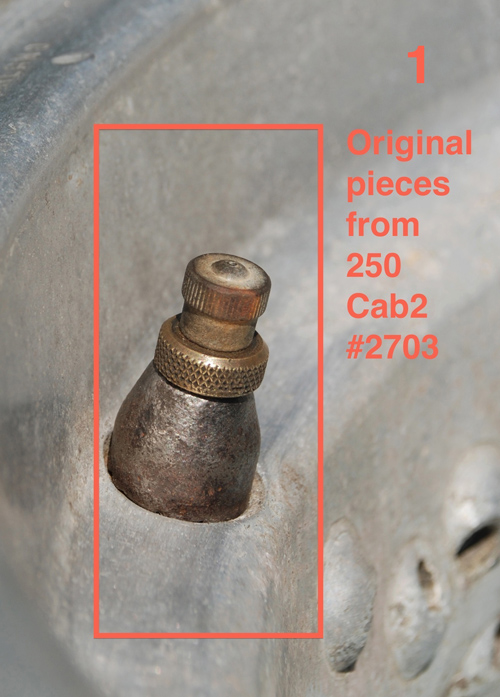

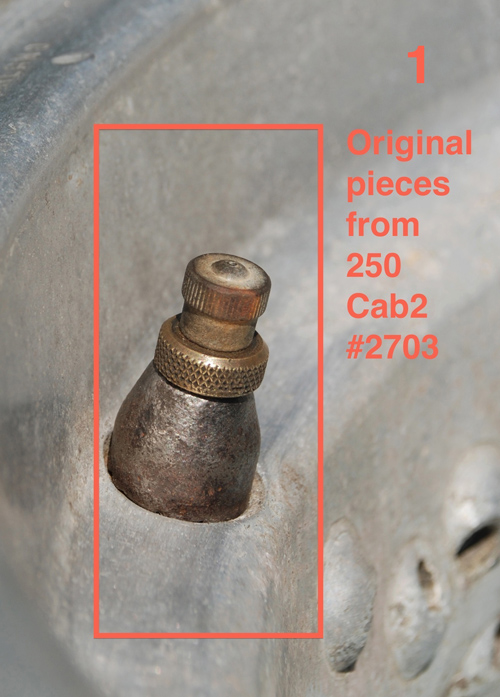

In the period from the late 1950’s through the late 1960’s Ferrari used

Pirelli tires which were equipped with a metal sleeve covering the

innertube nipple, along with a knurled nut to retain the sleeve and the

normal knurled metal cap that was common at the time. These three

pieces were found on the Borrani wire wheels as well as the cast alloy

wheels that were used on the 275’s and 330’s and later cars. These

pieces were used on the Pirelli tires and tubes, but were not used on

the Dunlop, Michelin or Firestone tires that were also supplied on the

Ferraris.

In 1980 I had a flat tire on my old 250 Cabriolet that was caused by

using a non-radial innertube in the old Pirelli Cinturato tires. I

replaced the “original?” Pirelli tires with new Michelins and in the

process found that the old steel sleeves would not fit the Michelin

tubes. Hence the sleeves and knurled retaining nuts were added to the

box of “extra” Ferrari bits. In 1988 Bobby Smith restored, and showed

at Pebble Beach, the beautiful 250 Ferrari P.F. Spyder #0737. Bobby had

made a set of sleeves and knurled retaining nuts to replace the now

rusty and damaged original pieces. Since that time most of the restored

Ferraris cars of that period have been shown with similar pieces.

The Problem

Michelin tubes are the choice among the U.S. restoration shops. They

are designed for radial tires and have a lap splice. Michelin invented

radial tires and they have a reputation for consistency and quality.

The new Michelin tubes have a slightly longer tube nipple and a

slightly shorter threaded section. Therefore, to cover the whole length

of the nipple and to seat properly in the wheel, the replacement

sleeves are considerably longer that the original pieces. They simply

look a little awkward and non-original. In addition to looking strange,

the short threaded section means that the retaining nuts have to be

removed to check the tire pressure or to inflate the tires and the caps

will not seat properly on the tube nipples. This is not a big problem

for street use, but is likely to be judged as a defect on show cars.

A Possible Solution

The photos show the original pieces assembled as they would have been

seen on a car in the late 1950’s,

the individual original pieces with the innertube nipple supplied by

Pirelli,

the replacement components that are available today, the shortened

sleeve and the innertube nipple grommet, a modified Michelin innertube

nipple and the complete modified assembly.

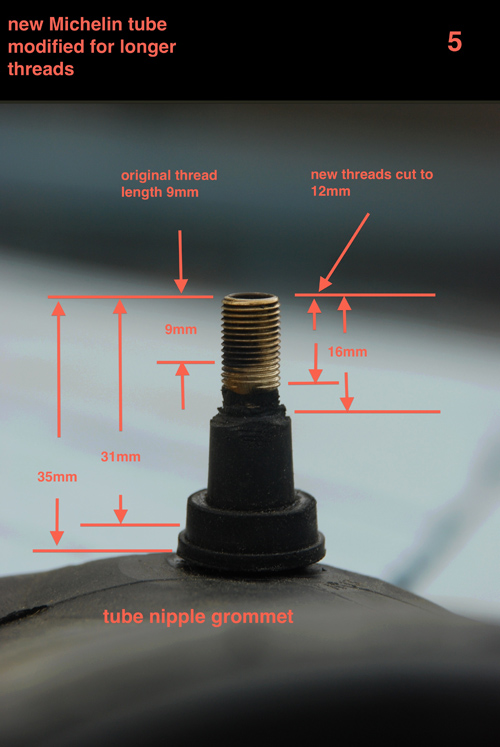

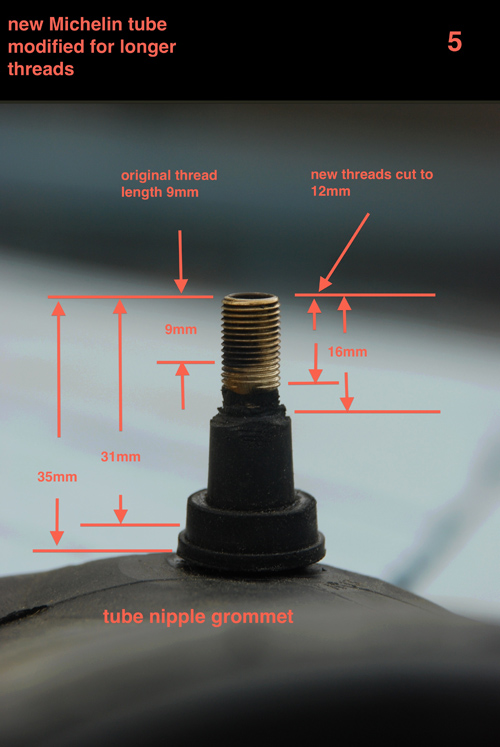

I believe that the following set of modifications and pieces will be a

solution to the problem. The new Michelin tubes can be modified as

shown in photo #5. This requires removing 5 mm of the rubber covering

over the brass section below the existing threads, then rethreading

this section to extend the threads to 16 mm long. I used a Dremel tool

with part #115 “high speed cutter” to reduce the diameter of the

exposed brass section. The die for cutting the threads is for Schrader

valves, 0.307”x 32 threads per inch. It is available from “e-taps.com.”

as part # “8v1-32 Schrader valve.” E-Taps phone is 321-953-3373, E-mail

is sales@e-taps.com. The piece shown in print #5 is

my first try. The results looked a lot better by using a Ridgid tubing

cutter to make the initial cut cleaner.

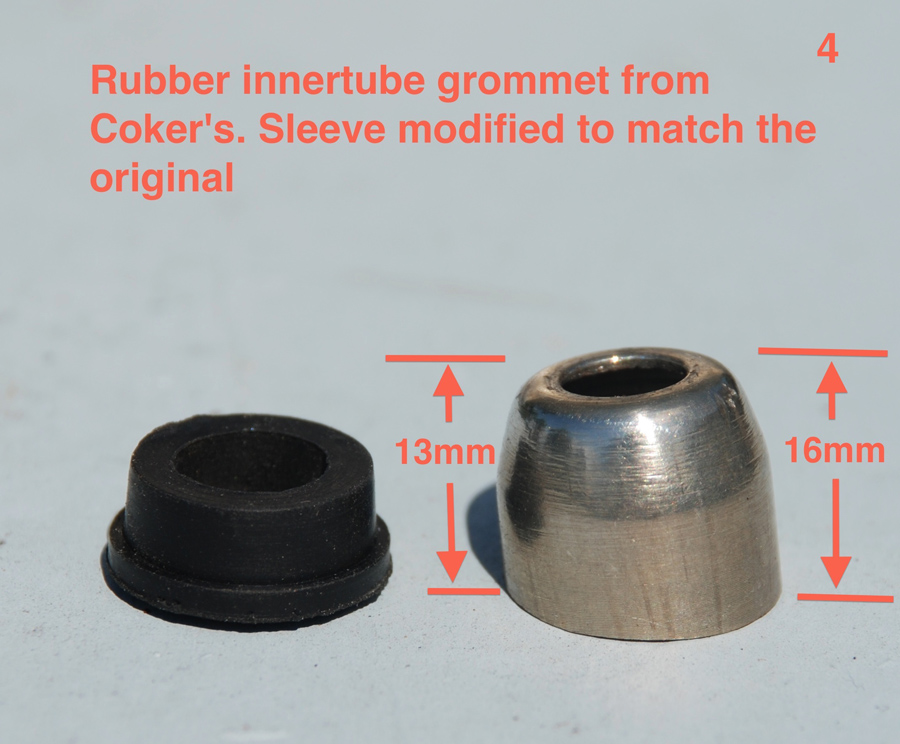

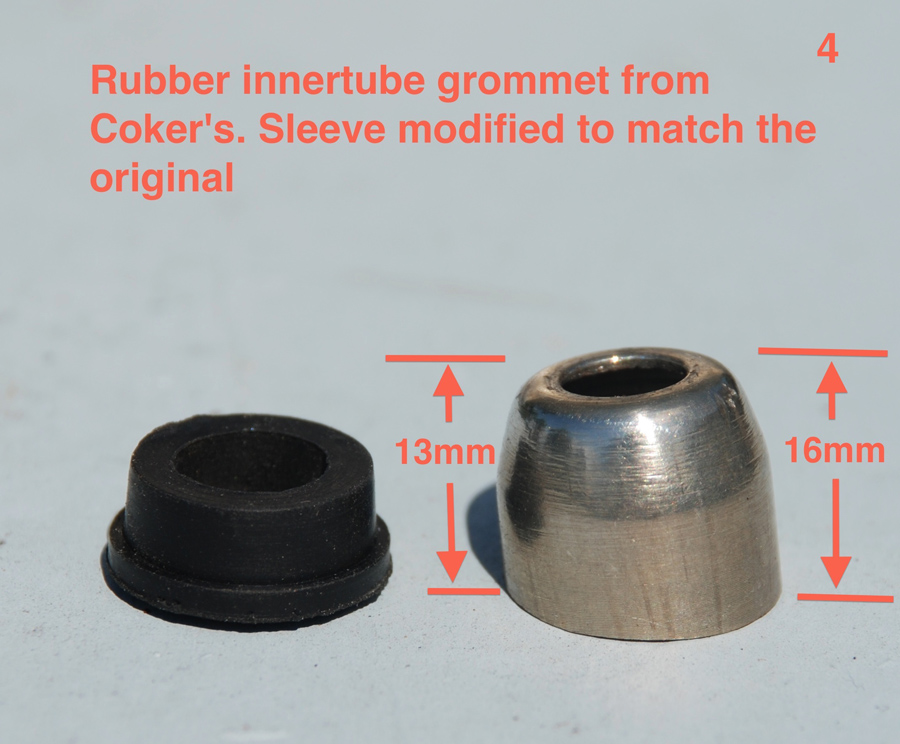

The second element in the cure is to use an innertube nipple grommet.

The grommets are designed to close the hole in the wheel to match the

smaller outside diameter of the nipple on the current supply of

innertubes. The grommets will also reduce the length of the innertube

nipple as it extends from the outside of the wheel rim. The grommets

are available from Coker Tire Company at 423-265-6368, as part

#“95002Grommet.”

The third element is the sleeve. The sleeves are supplied over-length

so they can be cut to allow for variations in the tube nipple lengths

from other manufacturers. Besides Michelin, innertubes may be available

in other countries or from other suppliers. The sleeves are 21.5 mm

long as supplied. To match the originals, they should be cut to 16 mm

on the long side and gradually tapered to 13 mm on the short side, as

shown in photo #4.

I hope that this suggestion will help in replicating an original look

to the current group of wheels and tires.